Xiamen SET Electronics Co., Ltd.

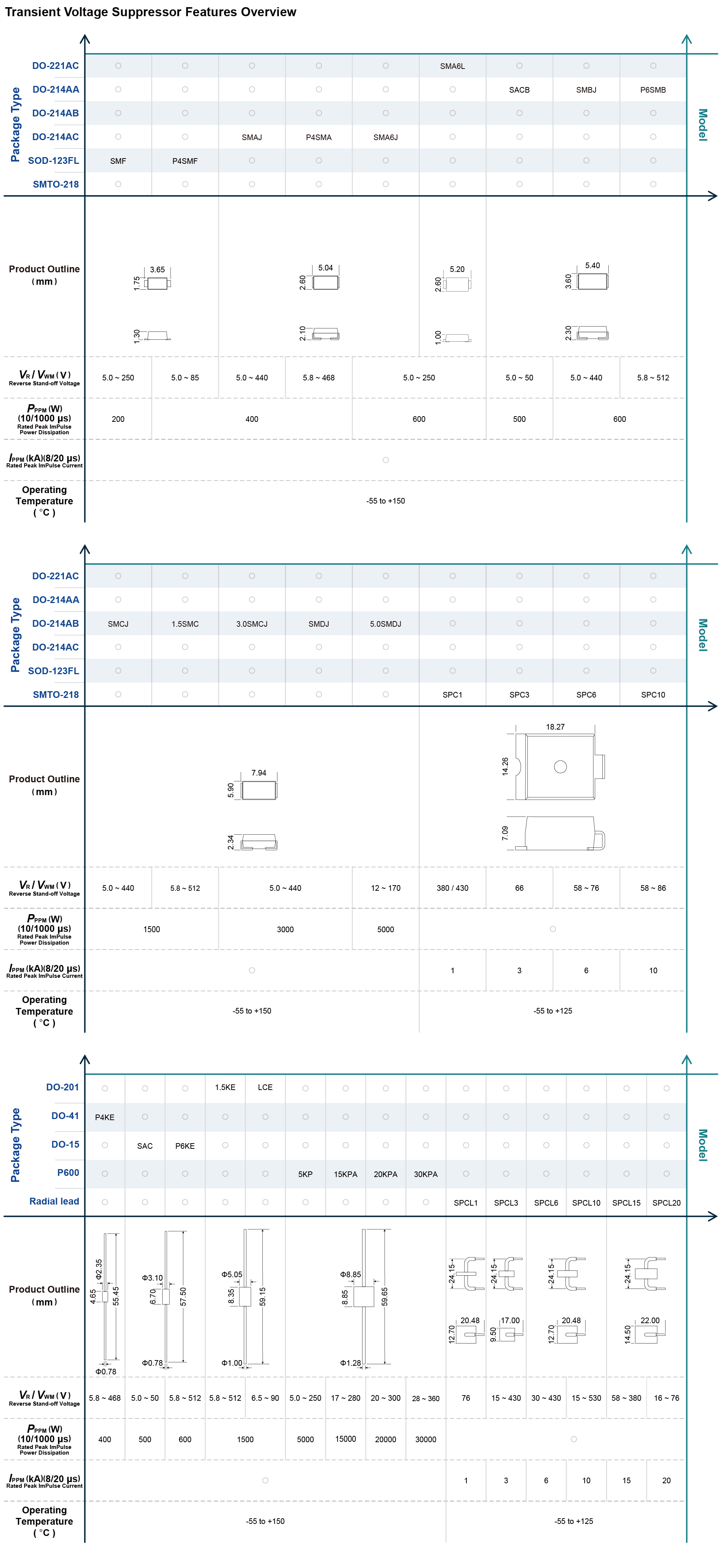

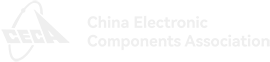

TVS Diodes are used to protect sensitive circuit from high-voltage transients.Their p-n junctions have a larger crosssectional area than those of a normal diode,allowing them to conduct large currents to ground without damage. SETsafe | SETfuse supplies TVS Diodes with peak power ratings from 200 W to 30 kW,and reverse standoff voltages from 5.0 V to 512 V.

VC

Clamping Voltage

Voltage across TVS in a region of low differential resistance that serves to limit the voltage across the device terminals.

— (IEC 61643-321)

— (JESD210A)

VR

Reverse Stand-off Voltage

Maximum voltage that can be applied to the TVS without operation.

NOTE : It is also shown as VWM (maximum working voltage (maximum d.c. voltage)) and known as rated stand-off voltage (Vso).

— (IEC 61643-321)

— (JESD210A)

IR

Reverse Leakage Current

Current measured at VR.

NOTE : Also shown as ID for stand-by current.

— (IEC 61643-321)

— (JESD210A)

VBR

Breakdown Voltage

Voltage across TVS at a specified current IT in the breakdown region.

— (IEC 61643-321)

— (JESD210A)

IPPM

Rated Random Recurring Peak Impulse Current

Maximum-rated value of random recurring peak impulse current that may be applied to a device.

— (IEC 61643-321)

— (JESD210A)

PM(AV)

Rated Average Power Dissipation

Maximum-rated value of power dissipation resulting from all sources, including transients and standby current, averaged over a short period of time.

— (IEC 61643-321)

— (JESD210A)

PPPM

Rated Random Recurring Peak Impulse Power Dissipation

Maximum-rated value of the product of rated random recurring peak impulse current (IPPM) multiplies by specified maximum clamping voltage (VC).

— (IEC 61643-321)

— (JESD210A)

CJ

Capacitance

Capacitance across the TVS measured at a specified frequency and voltage

— (IEC 61643-321)

— (JESD210A)

VFS

Peak Forward Surge Voltage

Peak voltage across an TVS for a specified forward surge current (IFS) and time duration.

NOTE : Also shown as VF.

— (IEC 61643-321)

— (JESD210A)

IFS

Forward Surge Current

Pulsed current through TVS in the forward conducting region.

NOTE : Also shown as IF.

— (IEC 61643-321)

— (JESD210A)

αV(BR)

Temperature Coefficient of Breakdown Voltage

The change of breakdown voltage divided by the change of temperature.

— (IEC 61643-321)

— (JESD210A)

IPP

Peak pulse Current

Peak pulse current value applied across the TVS to determine the clamping voltage VC for a specified wave shape.

— (IEC 61643-321)

— (JESD210A)

IT

Pulsed D.C. Test Current

Test current for measurement of the breakdown voltage VBR. This is defined by the manufacturer and usually

given in milliamperes with a pulse duration of less than 40 ms.

NOTE : Also shown as IBR .

— (IEC 61643-321)

— (JESD210A)

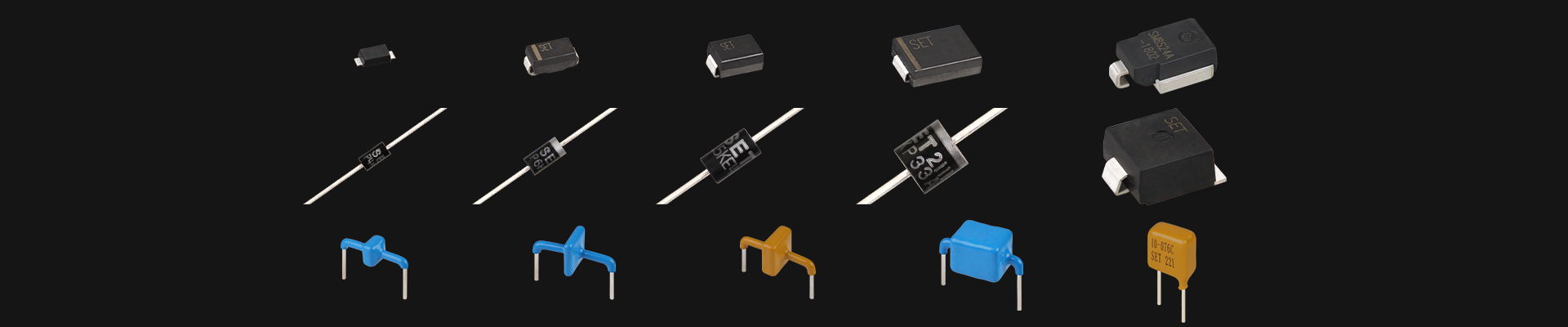

Through Hole, Surface Mount

● Communication Equipment

● Security & Protection

● Industrial Control Equipment

● Power Supply

● Automotive Electronics

● New Energy

● Lightning Protection

SETsafe | SETfuse Quality Policy

Provide Industry-Leading Products

Raw-materials Supplier

Select critical raw materials: Must be from a manufacturer with quality management system (ISO9001, IATF16949) certification.

Annual or Quarterly Audits.

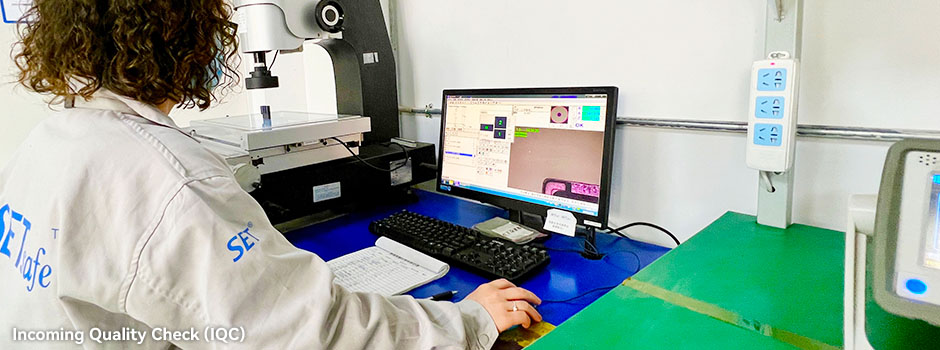

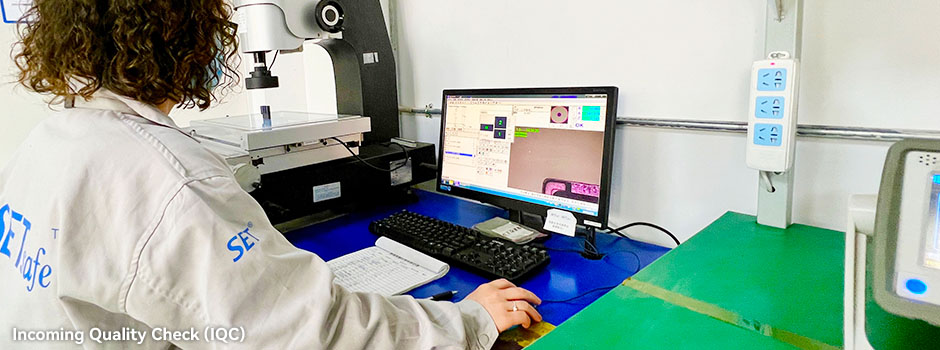

IQC (Incoming Quality Check)

AQL(MIL-STD-105E), Dimensions, Function, Visual Inspection, RoHS & REACH Test.

Document

Formulate corresponding incoming inspection specifications (01-QA-06-xxx) for each key material according to design data such as material technical indicators.

Testing Equipment and Tools

Tool Microscope, Curve Tracer, X-ray, Salt Spray Tester, Universal Material Testing Machine, Spectrum Analyzer, etc.

Manufacturing Process

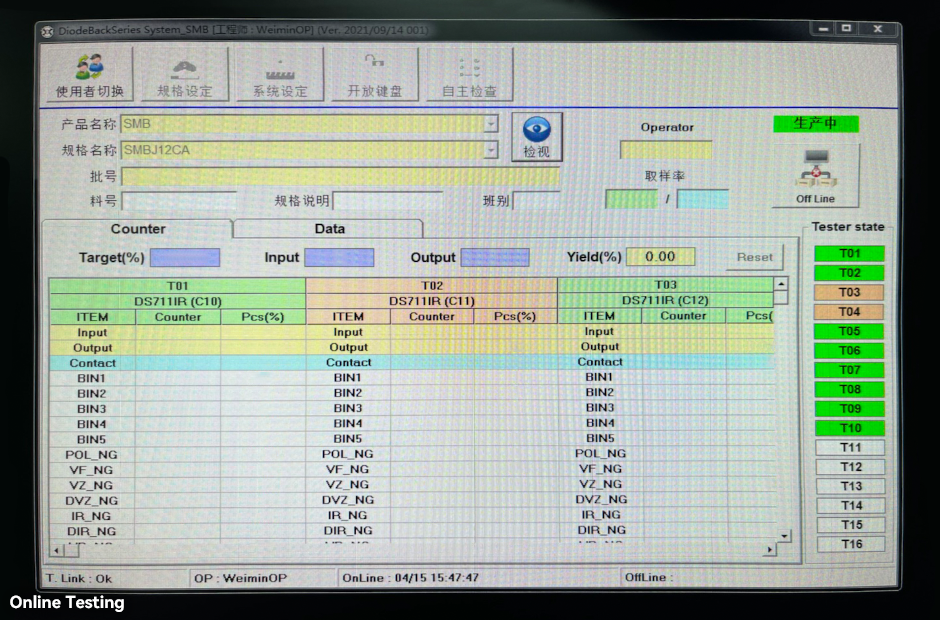

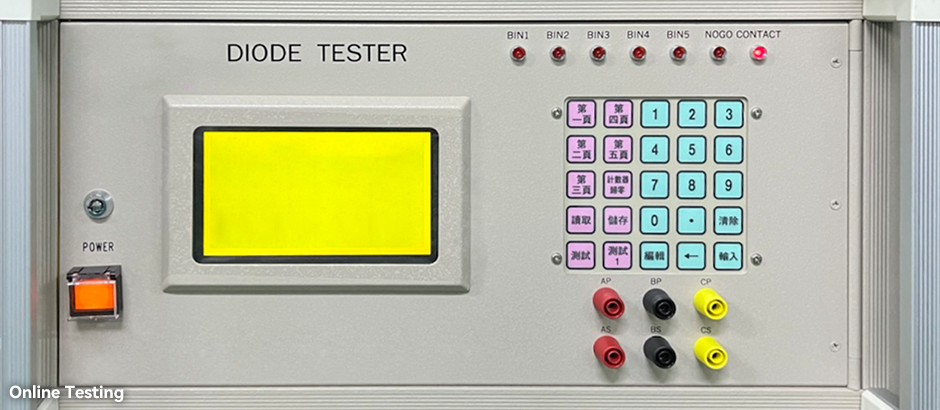

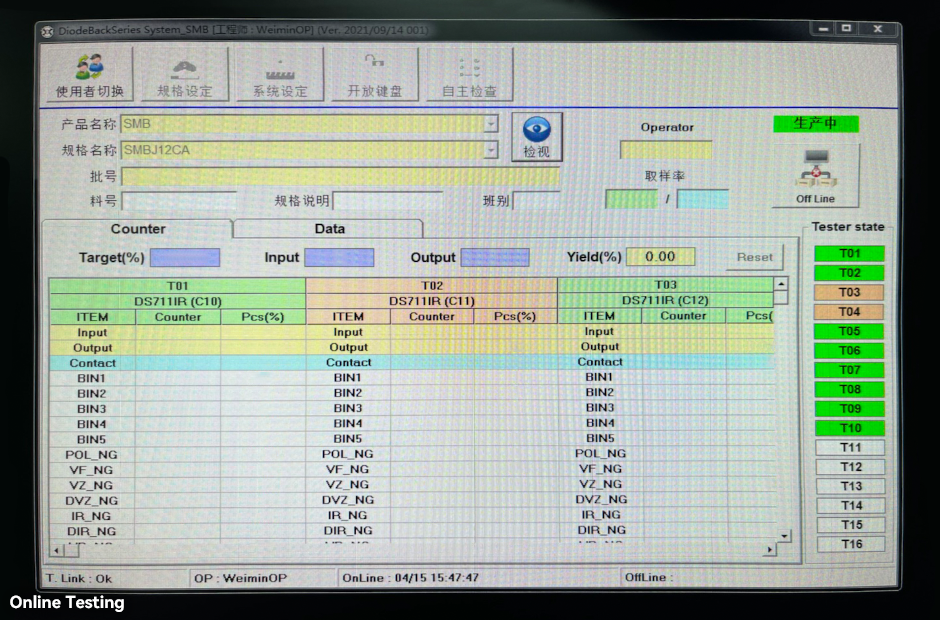

Online Inspection and Testing (Function 100% Automatic Testing).

Document

Process Flow Chart.

Failure Mode and Effects Analysis (FMEA).

Quality Control Flow Chart (QCFC).

Standard Inspection Procedure (SIP).

Work Instruction (WI).

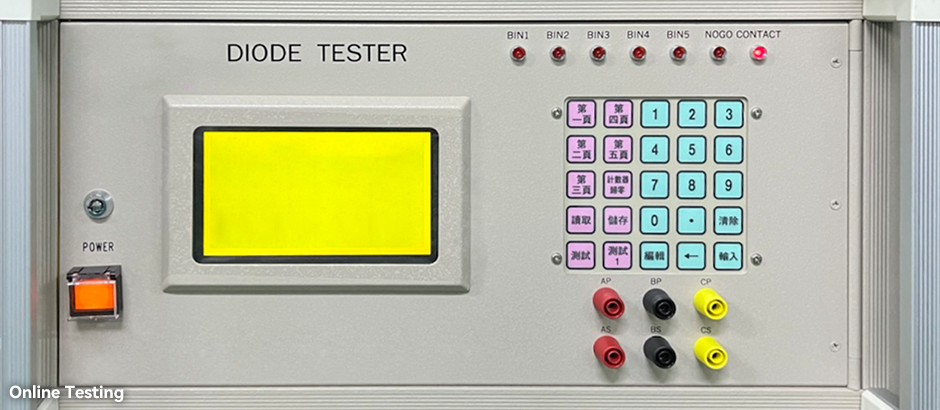

Online Testing and Inspection

Leakage, Breakdown Voltage, Surge test system (100% Automatic Testing).

100% Visual inspection, SMD Product 100% AI system.

etc.

IPQC (In Process Quality Control) Inspection

AQL(MIL-STD-105E), Dimensions Inspection, Function Test, Visual Inspection.

FQC ( Final Quality Control)

AQL(MIL-STD-105E), Dimensions Inspection, Function Test, Visual Inspection

Reliability Test

Test specification (01-TE-01-xxx).

Including Electrical Performance, Mechanical Performance, Soldering Performance, Environmental Test and Life Test. e.g in compliance with JEDEC, AEC-Q101 specification.

OQC (Outgoing Quality Control)

AQL(MIL-STD-105E), Packaging, Labeling, Quantity Inspection.

Management System

ISO9001, (TUV approved and issued certificate).

ISO14001, ISO45001, etc.

Click to view the certificate

Environmental

RoHS & REACH Compliant, Halogen Free.

Usage

1. TVS must be operated in the specified ambient temp.

2. Do not clean the TVS with strong polar solvent such as ketone, esters, benzene and halogenated hydrocarbon, to avoid damaging the encapsulating layer.

3.Please do not apply severe vibration, shock or pressure to TVS, to avoid element cracking.

Replacement

1.If TVS is visually damaged, please replace it.

2.TVS is a non-repairable product. For safety sake, please use equivalent TVS for replacement.

Storage

1. Storage Temp. Range: (-55 to 150) °C.

2. Do not store the TVS at the high temp., high humidity or corrosive gas environment, to avoid influencing the

solder- ability of the lead wires. The product shall be used up within 1 year after receiving the goods.

Environmental Conditions

1. TVS should not be exposed to the open air, nor direct sunshine.

2. TVS should avoid rain, water vapor or other condition of high temp. and high humidity.

3. TVS should avoid sand dust, salt mist, or other harmful gases.

Max. Typical Capacitance of TVS

The typical capacitance of TVS is listed in the specifications. Designers may refer to it when designing TVS in High frequency circuit.

Installation Mechanical Stress

1.Do not knock TVS when installing, to avoid mechanical damage.

2.Please do not apply severe vibration, shock or pressure to TVS, to avoid surface resin or element cracking.

Learn more

Click "Learn more" to jump to the Product Catalog (Datasheet) download page to download and read.

For more information, please contact SETsafe | SETfuse: sales@SETfuse.com.

Over Temperature Protection(85)

Over Temperature Protection(85)

Over Voltage Protection(234)

Over Voltage Protection(234)

Over Current Protection(59)

Over Current Protection(59)

Active Protection(18)

Active Protection(18)

Accessories(3)

Accessories(3)