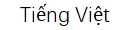

Lithium Battery Thermal Runaway Safety Protection SETsafe | SETfuse Solutions & Products

Why Is Safety Protection Against Lithium Battery Thermal Runaway Necessary

Lithium Battery Thermal Runaway Causes

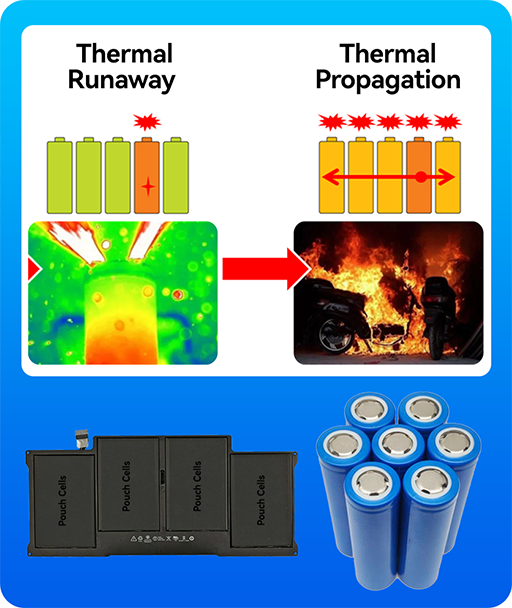

Thermal runaway in lithium-ion batteries occurs when an exothermic reaction spirals out of control, leading to rapid temperature increases, gas release, and potentially fires or explosions. The primary causes include:

Overheating:

Excessive external temperatures (e.g., exposure to heat sources or high ambient conditions) or internal heat generation (from overcharging or high discharge rates) can trigger thermal runaway. Typically, temperatures above 150°C (302°F) initiate exothermic reactions in the battery's components.

Overcharging:

Applying voltage beyond the battery’s safe limit (e.g., >4.2V for typical Li-ion cells) causes excessive lithium-ion flow, leading to cathode decomposition, electrolyte breakdown, and heat generation. This can destabilize the cell, initiating runaway.

Physical Damage:

Mechanical abuse, such as punctures, crushing, or vibration, can cause internal short circuits by damaging the separator between the anode and cathode. This allows direct electron flow, generating heat and sparking thermal runaway.

Internal Short Circuits:

Manufacturing defects (e.g., metal impurities or separator flaws) or dendrite growth (lithium plating during fast charging) can create unintended electrical paths inside the cell, leading to localized heating and runaway.

Electrolyte Decomposition:

At high temperatures or voltages, the liquid electrolyte (typically lithium salts in organic solvents) breaks down, releasing flammable gases like ethylene and carbon monoxide. These gases can ignite or build pressure, exacerbating the reaction.

External Short Circuits:

Faulty wiring or external damage connecting the positive and negative terminals can cause rapid discharge, generating excessive heat and triggering thermal runaway.

Battery Aging:

Over time, repeated charge-discharge cycles degrade the battery’s internal structure, increasing internal resistance and heat generation, which can lower the thermal runaway threshold.

Charger or BMS Failure:

A malfunctioning battery management system (BMS) or incompatible charger may fail to regulate voltage, current, or temperature, allowing conditions for thermal runaway to develop.

Once initiated, thermal runaway propagates as heat triggers further reactions (e.g., cathode decomposition at ~200°C, anode-electrolyte reactions, or separator melting), releasing more heat and gases. This feedback loop can lead to cell rupture, fire, or explosion if not mitigated by safety mechanisms like vents or thermal cutoffs.

Based on the aforementioned reasons, safety protection against lithium battery thermal runaway is necessary to ensure the safety of devices utilizing lithium batteries.

SETsafe | SETfuse Solutions & Products:

For the Technical Article on lithium battery thermal runaway safety protection Solutions: "Safety Device" - SETsafe | SETfuse solution products.

Product

Thermal-Link Alloy Type (ATCO)

Newly Designed YF Series for Cell Thermal Runaway Protection

Key Features:

Temperature-Sensitive Element: Compact Design With an Operating Temperature Accuracy of ±2°C.

Single-Use, Non-Resettable Action: Provides Dependable Over-Temperature Protection.

Environmental Compliance: Meets RoHS and REACH.

Customizable: Adjustable Parameters To Suit Specific Applications.

Applications

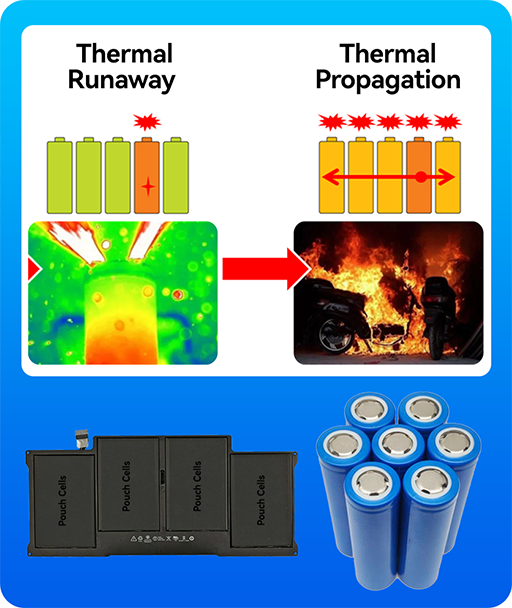

Suitable for Pouch Cells and Cylindrical Cells.

Operating Principle

The failure mode of lithium batteries often manifests as abnormal heat generation. SETsafe | SETfuse solutions utilize low-melting-point alloys as protective electrical connections. In the event of a single anomaly, the alloy melts, rapidly disconnecting the thermal and electrical pathways with the aid of a fluxing agent. This thermo-electrical separation minimizes the likelihood of thermal propagation, enhancing overall battery safety.

Partner with SETsafe | SETfuse to Transform Technical Challenges into Reliable Solutions

When you encounter technical challenges in selecting circuit protection components or designing system solutions, the professional engineering team at SETsafe | SETfuse is your trusted partner. Specializing in over-temperature, over-current, over-voltage, and active protection technologies, SETsafe | SETfuse offers comprehensive technical expertise and rapid response to meet your needs. Whether you require precise product parameter guidance or comprehensive system-level protection solutions, SETsafe | SETfuse delivers professional, practical, and efficient recommendations and support.

From initial design consultation and solution implementation to post-sales product assurance, we provide end-to-end collaboration, ensuring your project progresses seamlessly and reliably. For any inquiries or requirements, please contact us at: sales@SETfuse.com

Professional Circuit Protection, Supporting You from Concept to Production

Technical Article(For Reference Only)

Causes of Lithium Battery Thermal Runaway

Thermal runaway in lithium batteries refers to a rapid temperature increase under certain abnormal conditions, triggering uncontrollable chemical reactions that may lead to combustion or explosion. Key Causes Include:

Overcharging / Over-Discharging:

Exceeding safe voltage ranges leads to electrolyte decomposition, gas generation, or electrode material degradation.

Short Circuits:

Internal short circuits (e.g., manufacturing defects, separator damage) or external short circuits (e.g., wiring faults) cause high currents and localized overheating.

High-Temperature Environments:

External heat sources (e.g., fire, prolonged sun exposure) or poor heat dissipation push battery temperatures beyond critical thresholds.

Mechanical Damage:

Impacts, crushing, or punctures compromise internal structures, leading to short circuits or electrolyte leakage.

Manufacturing Defects:

Impurities in electrode materials, separator flaws, or improper assembly increase thermal runaway risks.

Battery Aging:

Material degradation from repeated cycling increases side reactions, potentially triggering thermal runaway.

Phenomena

Phenomena of Thermal RunawayThe thermal runaway process is typically accompanied by the following:

Rapid Temperature Increase: Battery temperatures can rise to hundreds of degrees Celsius.

Gas Release:

Electrolyte decomposition generates flammable gases (e.g., H₂, CO, CH₄), causing cell swelling or venting.

Smoke and Flames:

Cell casing rupture releases toxic fumes, potentially leading to combustion or explosion.

Electrical Anomalies:

Voltage fluctuations and rapid capacity loss.

Physical Deformation:

Cell swelling, rupture, or electrolyte leakage.

Solutions

Solutions Preventing and mitigating thermal runaway requires a multi-faceted approach, encompassing design, manufacturing, usage, and emergency management.

Enhanced Battery Design:

Material Optimization:

Use high-thermal-stability cathode materials (e.g., lithium iron phosphate [LFP] instead of nickel-cobalt-manganese [NCM]), high-temperature-resistant electrolytes, and ceramic-coated separators.

Safety Devices:

Incorporate explosion-proof valves, thermistors, or over-temperature fuses to release pressure or interrupt current flow promptly.

Thermal Management:

Implement efficient battery management systems (BMS) with liquid or air cooling to regulate temperatures.

Manufacturing Quality Control:

Enhance production process consistency to minimize impurities and defects.

Rigorously screen and test individual cells to eliminate internal short-circuit risks.

Battery Management System (BMS) Optimization:

Real-time monitoring of voltage, current, and temperature to detect anomalies promptly.

Implement overcharge, over-discharge, and over-temperature protection mechanisms to automatically disconnect circuits.

Integrate AI algorithms to predict thermal runaway risks.

Conclusion

Lithium battery thermal runaway results from a complex interplay of factors across design, manufacturing, and usage. By optimizing materials, enhancing BMS capabilities, standardizing usage protocols, and implementing robust emergency measures, thermal runaway risks can be significantly reduced. SETsafe | SETfuse’s COB and ATCO solutions provide precise, reliable, and customizable thermal protection, ensuring core safety for lithium battery applications.

Rechargeable Battery

Rechargeable Battery Lithium Battery Thermal Runaway

Lithium Battery Thermal Runaway Electric Power Tool

Electric Power Tool New Energy

New Energy PV Power Generation

PV Power Generation Wind Power Generation

Wind Power Generation Energy Storage Batteries

Energy Storage Batteries Energy Storage System (ESS)

Energy Storage System (ESS) Electric Vehicles

Electric Vehicles EV Charging Stations

EV Charging Stations Light Electric Vehicles

Light Electric Vehicles Home Appliances

Home Appliances Small Household Appliances

Small Household Appliances Large Home Appliance

Large Home Appliance Home Appliance Component

Home Appliance Component Kitchen Appliances (Hotplates ...)

Kitchen Appliances (Hotplates ...) Air Fryer

Air Fryer Coffee Machine

Coffee Machine Electric Iron

Electric Iron Smart Toilet

Smart Toilet Personal Digital Products

Personal Digital Products Lifestyle Appliances

Lifestyle Appliances Office Equipment

Office Equipment Walkie Talkie

Walkie Talkie Medical Analysis Instrument

Medical Analysis Instrument Medical Auxiliary Facility

Medical Auxiliary Facility Medical Instrument

Medical Instrument Lighting

Lighting Indoor Lighting

Indoor Lighting Outdoor Streetlight

Outdoor Streetlight Power Supply

Power Supply Power Supply (Power < 20 Watts)

Power Supply (Power < 20 Watts) HVDC in Data Centers

HVDC in Data Centers Power Supply Unit (PSU)

Power Supply Unit (PSU) Battery Backup Unit (BBU)

Battery Backup Unit (BBU) Uninterruptible Power Supply (UPS)

Uninterruptible Power Supply (UPS) Telecommunication

Telecommunication Automotive

Automotive Power Strip

Power Strip Surge Protection Power Strip

Surge Protection Power Strip Security & Protection

Security & Protection Tethered Drone

Tethered Drone Industrial Robot

Industrial Robot Humanoid Robot

Humanoid Robot Service Robot

Service Robot Specialty Robot

Specialty Robot Agricultural Irrigation Equipment

Agricultural Irrigation Equipment Smart Agricultural Greenhouse

Smart Agricultural Greenhouse Rail Transit Facility

Rail Transit Facility Rail-Vehicle

Rail-Vehicle Railway Power Supply

Railway Power Supply Fuel Dispenser

Fuel Dispenser Traffic Control System

Traffic Control System Traffic Signal Light

Traffic Signal Light Commercial Cleaning Equipment

Commercial Cleaning Equipment Delivery Locker (Drone)

Delivery Locker (Drone) Vending Machine

Vending Machine Lightning Protection Components

Lightning Protection Components HVAC Rooftop Systems

HVAC Rooftop Systems Outdoor Electric Wall Mounted Heater

Outdoor Electric Wall Mounted Heater Flag Explain

Flag Explain